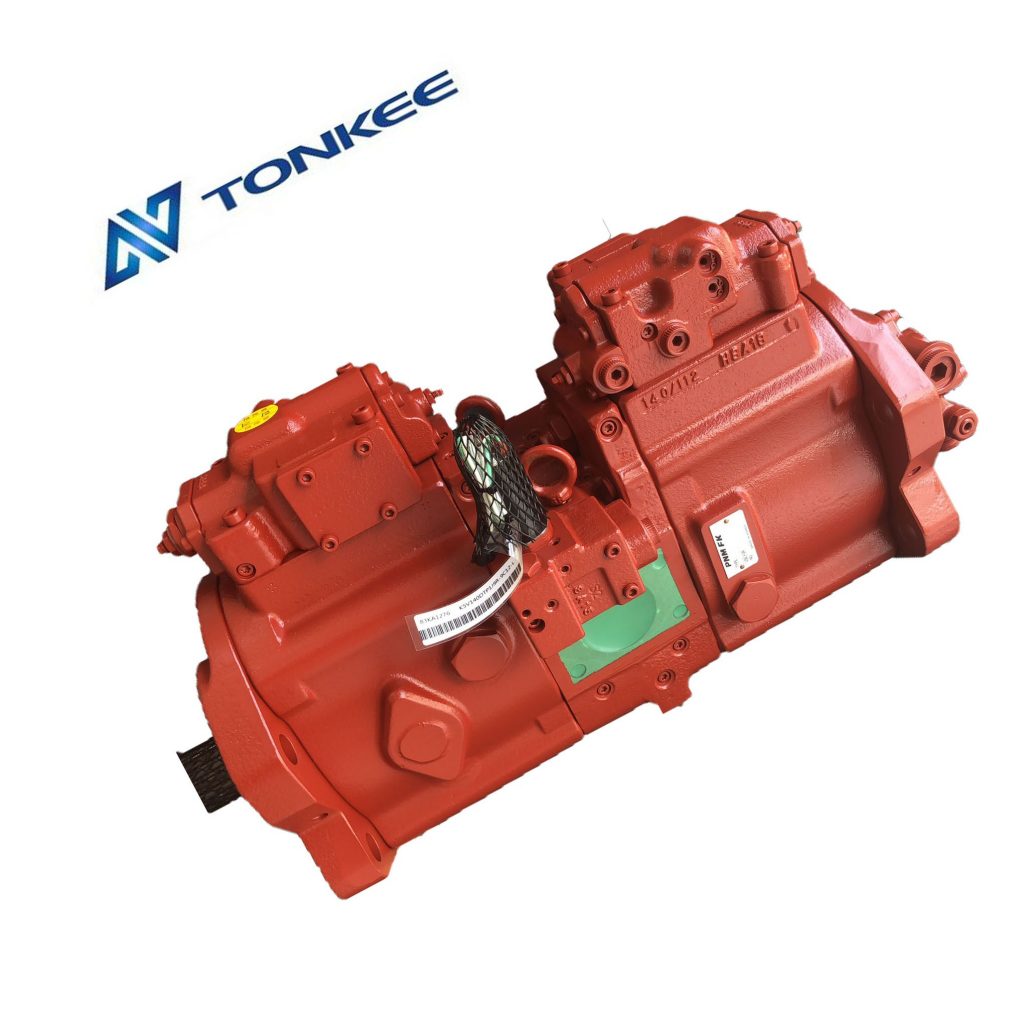

Hydraulic pumps used in excavators are typically of two types: piston pumps and gear pumps.

Piston pumps, which include axial and radial types, are preferred for their efficiency and ability to handle high pressures. Gear pumps are simpler but are often used in auxiliary systems due to their lower efficiency.

Flow Rate:

The flow rate of the hydraulic pump is a crucial specification. It is usually measured in liters per minute (LPM) or gallons per minute (GPM). The flow rate determines the excavator's speed and capacity for handling different attachments and tasks. For heavy-duty excavators, a higher flow rate is necessary to maintain productivity.

Pressure Rating:

The pressure rating, often measured in bar or psi, indicates the maximum pressure the hydraulic pump can handle. Excavators require high-pressure hydraulic systems to perform tasks like digging through tough terrain and lifting heavy loads. The pump's pressure rating should match the excavator's operational requirements.

Size and Dimensions:

The size and dimensions of hydraulic pump parts should be compatible with the excavator's design and other components. These parts must fit within the allotted space in the machinery, and their layout should facilitate maintenance and repairs when necessary.

Material and Durability:

Hydraulic pump parts must be made from high-quality materials that can withstand the demanding conditions of construction sites.

Components such as the housing, gears, pistons, and seals should be durable, resistant to corrosion, and capable of withstanding significant wear and tear.

Seal Types:

Seals are crucial to prevent fluid leakage and maintain system integrity. Common seal types include O-rings, lip seals, and V-rings. Proper sealing ensures that the hydraulic pump remains efficient and minimizes downtime for maintenance and repairs.

Efficiency and Performance:

Efficiency is a critical factor for hydraulic pumps in excavators. Highly efficient pumps reduce energy consumption and improve the overall performance of the machine. Modern hydraulic pumps often incorporate advanced technologies like variable displacement to optimize efficiency.

Control Mechanism:

Many hydraulic pumps for excavators feature adjustable control mechanisms. These controls allow operators to vary the flow rate and pressure to match specific tasks, making the excavator more versatile and adaptable to different working conditions.

Maintenance and Serviceability:

Ease of maintenance is crucial to minimize downtime and repair costs. Hydraulic pump parts should be designed for easy access and replacement when required. Comprehensive documentation and support from the manufacturer can also simplify maintenance procedures.

Compatibility and Interchangeability:

The hydraulic pump and its parts should be compatible with the excavator's make and model. In some cases, interchangeable parts can be advantageous, allowing for easier repairs and cost-effective maintenance.

English

English Русский язык

Русский язык